When Things Start Getting Out of Balance as You Scale.

Optimizing Production Planning Across Industries – Your Solution to Manufacturing Challenges

ZENAPS revolutionizes production planning, eliminating chaos and empowering your business to achieve precision and efficiency—so you can focus on driving growth.

Here’s how ZENAPS leverages three critical pillars of manufacturing efficiency, each designed to ensure smooth, timely, and optimized production operations.

Time & Action Planning

Coordinating tasks and milestones for on-time order fulfillment.

Production Planning

Streamlining workflows with real-time data and automated scheduling.

Components Planning

Ensuring material availability and resource allocation for peak efficiency.

ZENAPS Transformation

Production delays vs. Optimized flow with ZENAPS

ZENAPS Optimized Flow (Solution Benefits)

-

⚡ Automatic Sequencing & Alignment

Smooth production flow without bottlenecks. -

📈 Smart Scheduling

Real-time, automated scheduling boosts efficiency. -

✅ Efficient Job Flow & On-Time Delivery

ZENAPS adapts to capacity shifts, reassigning jobs while keeping tasks on schedule to meet deadlines. -

💰 Cost Savings

Reduced downtime and lower costs, enhancing profitability. -

🌟 Quality Management Aided by Workflows

Structured workflows improve quality consistency and production standards.

Production Delays (Current Challenges)

-

⏳ Frequent Bottlenecks

Production slows due to lack of real-time updates. -

📉 Reduced Efficiency

Manual scheduling creates inefficiencies. -

🕒 Misaligned Scheduling Late Start & Early Finish

Ignoring task dependencies causes delays with "late starts" and "early finishes, disrupting workflow. -

💸 Increased Costs

Delays lead to higher operational costs. -

❌ Poor Quality Management

Lack of structured workflows results in quality inconsistencies.

The Critical Need for a Advance Planning Solution

-

Coordinated tasks across departments ensure seamless order shipment.

Multiple Interdependent Actions

-

Manage dependent and independent steps to maintain smooth workflow execution

Dependent & Independent Process Steps

-

Track and communicate progress regularly to ensure task alignment and timely handoffs.

Continuous Follow-Ups

-

Ensure smooth collaboration and communication across departments for efficient task completion.

Cross- Department Coordination

-

Access a single platform for complete visibility and progress tracking of each order

Centralized Sales Order Visibility

-

Automate routine tasks to enforce Standard Operating procedures compliance and improve operational efficiency.

SOP Compliance & automation

Challenges Faced By Manufacturing Business

How and why we developed this product.

-

The inadequacies of traditional ERP systems often necessitate frequent human input to correct or manage processes, which slows down operations and increases the risk of errors.

Manual Intervention

-

Lack of coordination between different teams, causing them to work separately instead of together, which leads to inefficiencies.

Departmental Silos

-

Difficulty in tracking the progress of production in real-time, which can lead to scheduling conflicts and unexpected downtime

Limited Visibility

-

Not informing customers about production delays in time, leading to unhappy clients and potential loss of business.

Delayed Customer Communication

-

Machines and resources aren’t being used to their full potential, leading to wasted time and lower overall productivity.

Underutilization of Capacity and Inefficient Production

Common Traditional Approaches to problem-Solving

Old methods can’t solve new problems—it's time to think differently.

How Traditional Problem-Solving Methods lead to Underutilized Assets and Overburdened teams

-

Relies on manual data entry and fragmented information, increasing the risk of errors and oversight.

Spreadsheet Dependency: Managing Complexity

-

Focuses on immediate needs, often leading to last-minute adjustments and missed opportunities

Just-in-Time’ Planning: A Reactive Strategy

-

Separate teams plan in isolation, causing misalignment and inefficiencies across operations.

Planning in Silos: Lack of Collaboration

-

Traditional methods often struggle with accurate demand forecasting, leading to production mismatches

Inadequate Forecasting: Poor Demand Predictions

Your All-in-One Solution for Production Planning—A Game-Changing Software Tailored to Tackle Complex Challenges and Empower Your Manufacturing Success. Contact

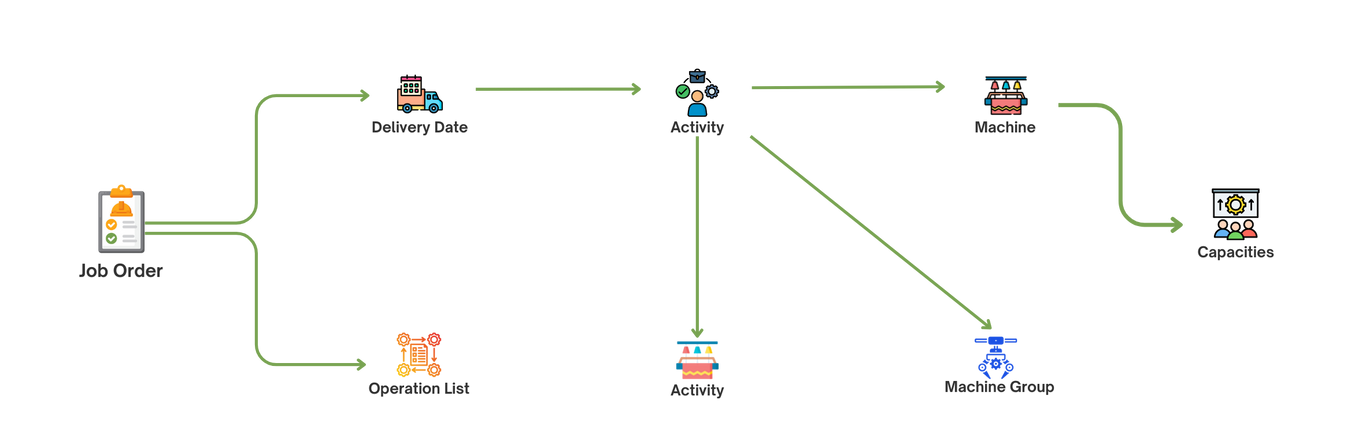

How ZenAPS Works: Simplifying Production Planning Step-by-Step

The ZENAPS Advantage: Seamless Planning, Powerful Results

Job Order Entry

Provides job order details (e.g., delivery dates, linked orders) to begin the process.

Automated Data Collection & Analysis

ZENAPS gathers critical data and assesses requirements based on delivery schedules, linked orders, and production needs.

Automated Scheduling & Execution

The system prompts for capacity groups, clubbing options, and splitting needs, ensuring optimal resource allocation.

Capacity and Resource Confirmation

ZENAPS schedules tasks based on confirmed plans, automatically adjusting timelines for any changes or unexpected events.

Continuous Real-Time Monitoring & Adjustments

Receive instant alerts and make live adjustments to maintain efficiency.

Drive Efficiency, Cut Costs, Boost Profitability

Drive Efficiency, Cut Costs, Boost Profitability

-

🌐 100% Production and WIP Visibility

Complete, real-time insight into all stages of production, including Work-In-Progress (WIP), from planning to completion. -

📦 High On-Time Delivery Rates

Meet your delivery commitments with confidence and reliability. -

🕒 Significantly Reduced Delays

Minimized downtime and enhanced resource efficiency keep you on schedule. -

💼 Optimized Resource Utilization

Leverage your production capacity to the fullest, reducing waste and boosting output.

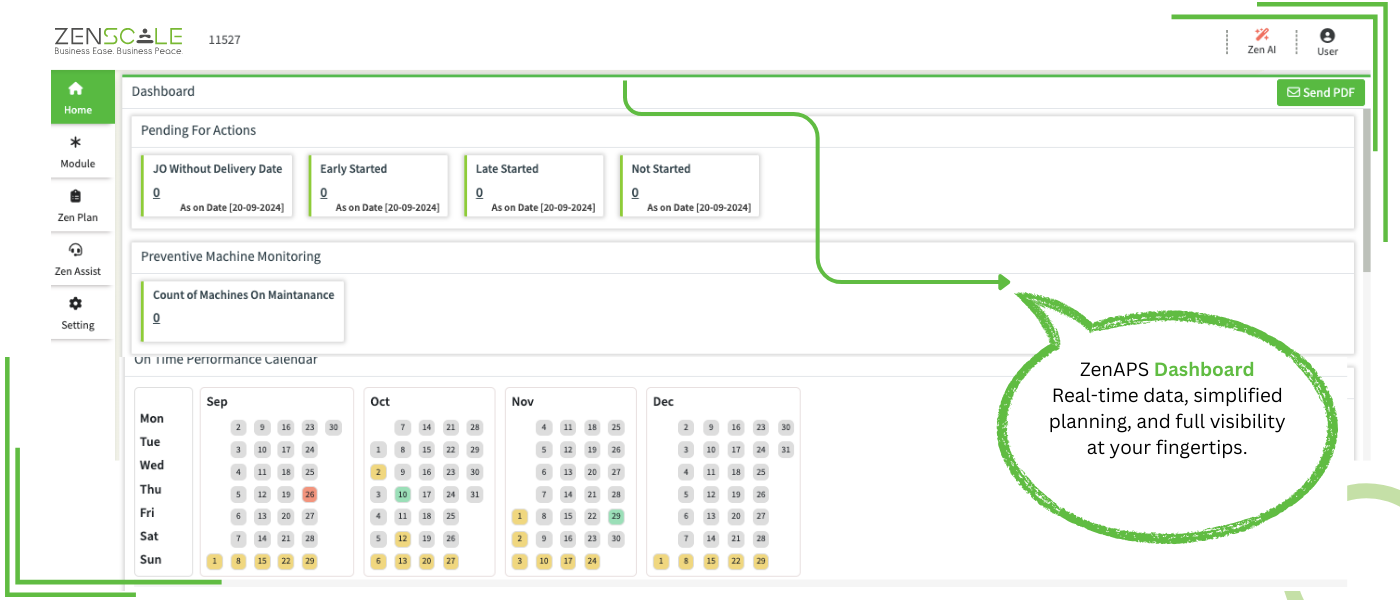

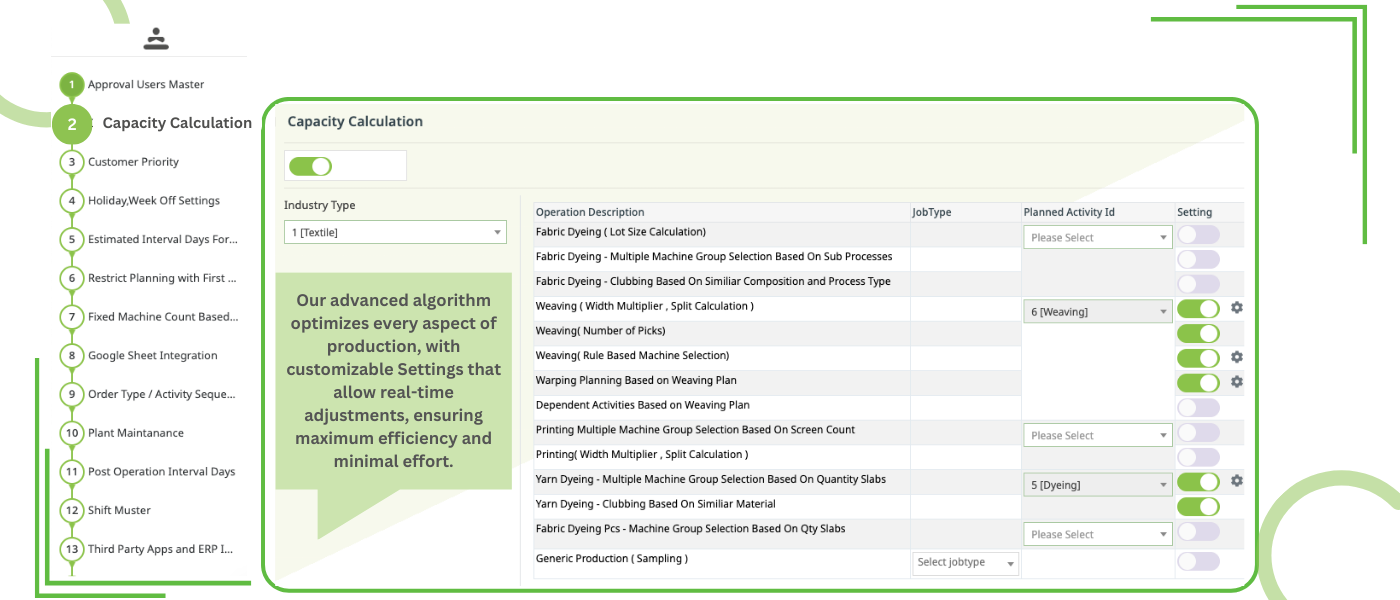

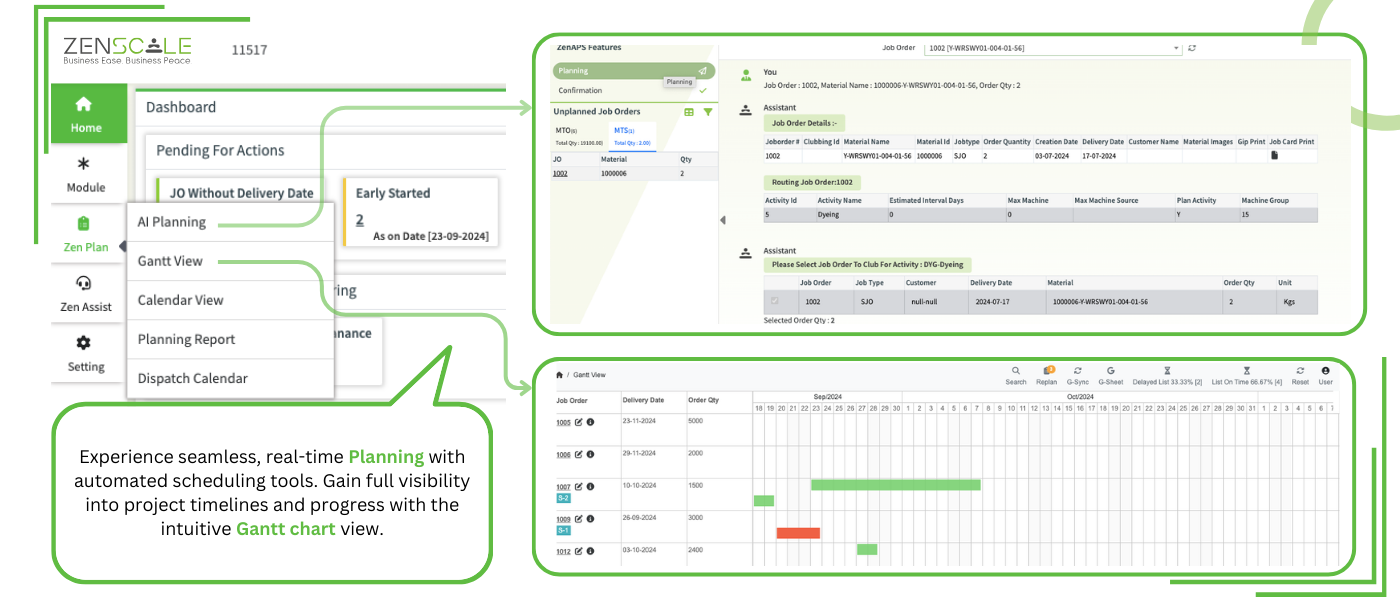

Glimpse of Our Smart Production Planning Solution

Discover smart, integrated tools designed for seamless planning and real-time insights

Advanced planning with intuitive insights through Gantt Chart visualization

Driving results in every industry

Tailored for Excellence Across Industries

ZENAPS is designed to address the unique production planning challenges faced by diverse industries. From textiles and garments to engineering and FMCG, our Advanced Planning Solution adapts seamlessly to optimize workflows, reduce delays, and ensure on-time delivery.

Whether managing complex dependencies or streamlining multi-stage processes, ZENAPS empowers businesses to achieve precision, efficiency, and growth in every sector.

Customer Speaks

Contact

Feel free to contact us if you need any assistance, any help or another question.